Introduction

When it comes to fabrics, understanding the weight is crucial for selecting the right material for your project. Two common terms you might encounter are GSM and GRM. While they might seem similar, they refer to different aspects of fabric measurement. In this blog post, we will explore why we measure GSM and GRM and clarify the differences between these two terms.

What is GSM?

GSM stands for grams per square meter. It is a metric measurement that indicates the weight of the fabric. This measurement is essential because it helps determine the fabric’s thickness, density, and suitability for various applications.

Why Measure GSM?

- Fabric Weight and Thickness: GSM provides a clear understanding of how thick or heavy the fabric is. For instance, a fabric with a high GSM is thicker and heavier, making it suitable for winter garments or upholstery. Conversely, a low GSM fabric is lighter and ideal for summer clothing or lightweight curtains.

- Durability and Strength: Higher GSM fabrics tend to be more durable and robust, which is important for items that need to withstand wear and tear, such as workwear or heavy-duty bags.

- Application Suitability: Different projects require different fabric weights. Knowing the GSM helps in selecting the right fabric for specific uses, ensuring the final product performs as expected.

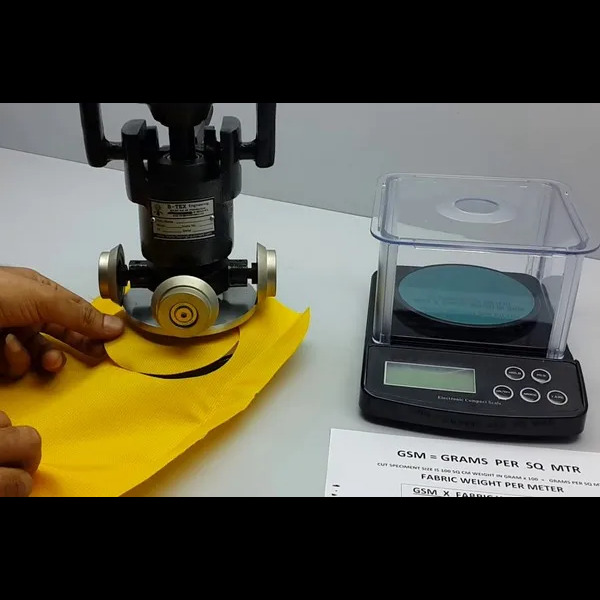

How to Measure GSM

To measure GSM, a small sample of the fabric is weighed, and the weight is then scaled to a square meter. This provides a standardized weight, allowing for easy comparison between different fabrics.

What is GRM?

GRM stands for grams per running meter. Unlike GSM, which measures weight over a fixed area, GRM measures the weight of a continuous length of fabric. This measurement is more commonly used in commercial fabric transactions where fabrics are sold by length rather than area.

Why Measure GRM?

- Commercial Transactions: In the textile industry, fabrics are often sold by the meter. GRM provides a practical measurement for pricing and purchasing, ensuring buyers know exactly what they are getting.

- Consistent Quality: Measuring GRM helps maintain consistency in fabric quality over long runs. It ensures that each meter of fabric meets the required weight specifications, which is crucial for large-scale production.

- Ease of Handling: Knowing the GRM is helpful for logistics and handling. It allows for better planning in terms of storage, transportation, and processing of fabric rolls.

How to Measure GRM

To measure GRM, the weight of a specified length of fabric (usually one meter) is taken. This measurement is straightforward and provides a direct understanding of the fabric’s weight per running meter.

Key Differences Between GSM and GRM

- Measurement Basis: GSM measures weight based on area (square meter), while GRM measures weight based on length (running meter).

- Usage Context: GSM is widely used to determine fabric weight and suitability for specific applications. GRM is primarily used in commercial settings for pricing and purchasing fabric by length.

- Application Specificity: GSM is more useful for understanding fabric characteristics like thickness and durability. GRM is more practical for logistical and transactional purposes in the textile industry.

Conclusion

Understanding GSM and GRM is essential for anyone involved in fabric selection, whether you’re a designer, manufacturer, or hobbyist. GSM helps you determine the fabric’s weight, thickness, and application suitability, while GRM is crucial for commercial transactions and logistical planning. By measuring both, you ensure you choose the right fabric for your needs and maintain consistency in your projects.

Call to Action

Have more questions about fabric measurements? Leave a comment below, and don’t forget to subscribe to our blog for more insights into the world of textiles!